Delivering better quality fresh food

Advances in technology are also playing an important role in today’s food supply chain. Active and passive monitoring ensures an unbroken cold chain. Software systems help manage packaging and product inventory and compliance reporting. Through automation, commissioning is fast and precise.

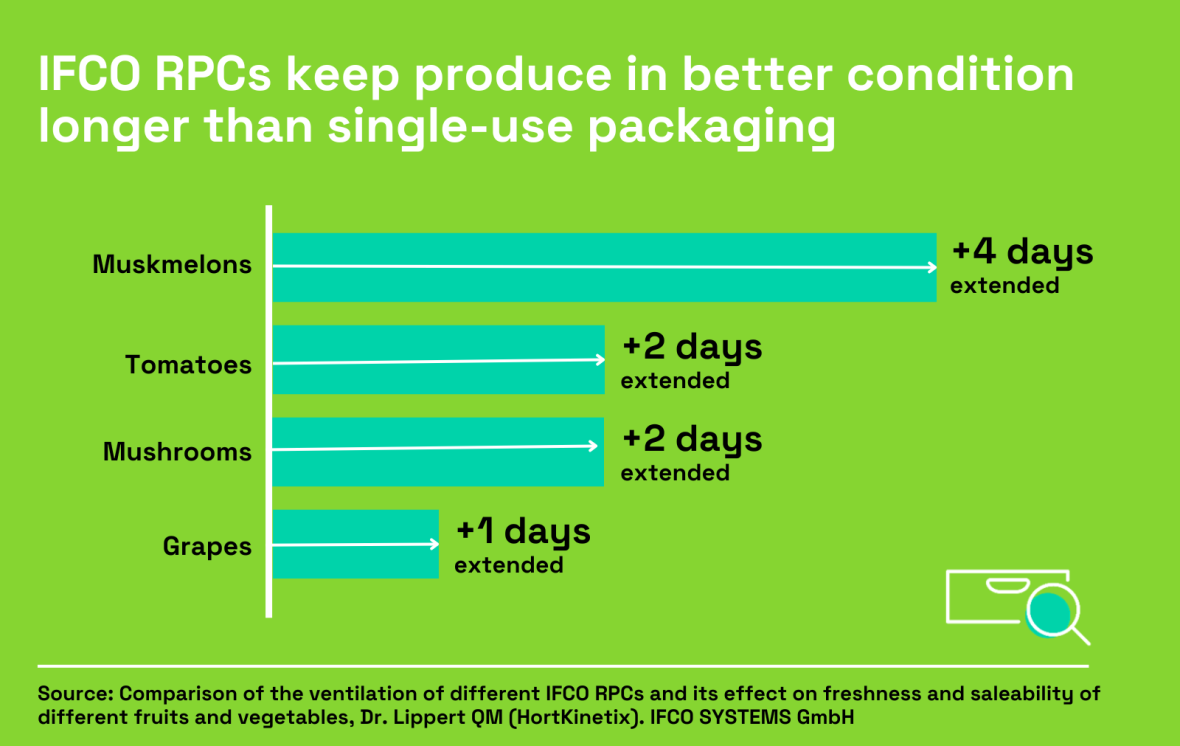

Among pooling providers, IFCO is a leader in digitalization. Our IFCO RPCs are ready for tomorrow’s tech trends, for example, with Data Matrix labels that enable track-and-trace of shipments. Innovation such as this helps reduce delays in disposition, shortens the time produce spends in transport, and maintains food freshness and quality. IFCO RPCs enable faster distribution and commissioning, a more efficient supply chain results in higher-quality produce.