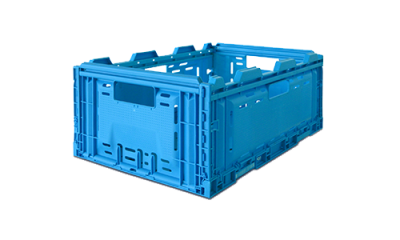

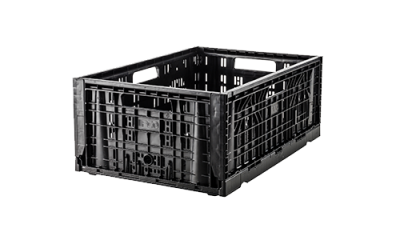

Unsere RPCs.

Für jedes frische Produkt die richtige Steige.

choose Country & Language: / Deutsch

Unsere RPCs.

Für jedes frische Produkt die richtige Steige.

Wir wissen, wie wichtig die perfekte Lösung für Ihre frischen Produkte ist, deshalb bieten wir wiederverwendbare Verpackungslösungen für jeden Bedarf an. Mit über 70 Modellen sind unsere displayfähigen Mehrweg-Verpackungsbehälter (RPCs) in zahlreichen Größen erhältlich. Für den sicheren Transport von frischem Obst und Gemüse, von Fleisch, Fisch und Meeresfrüchten, Eiern, Backwaren sowie Feinkost und Fertiggerichten. Echte Arbeitstiere sozusagen.

Unsere immer wieder verwendbaren RPCs reduzieren außerdem Lebensmittelverschwendung, bringen Kosteneinsparungen, verlängern die Haltbarkeit des Erzeugnisses und sorgen für nachhaltigere Abläufe in Ihrem Betrieb. Machen wir Schluss mit den Einwegverpackungen.

Showing series

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für

empfohlen für