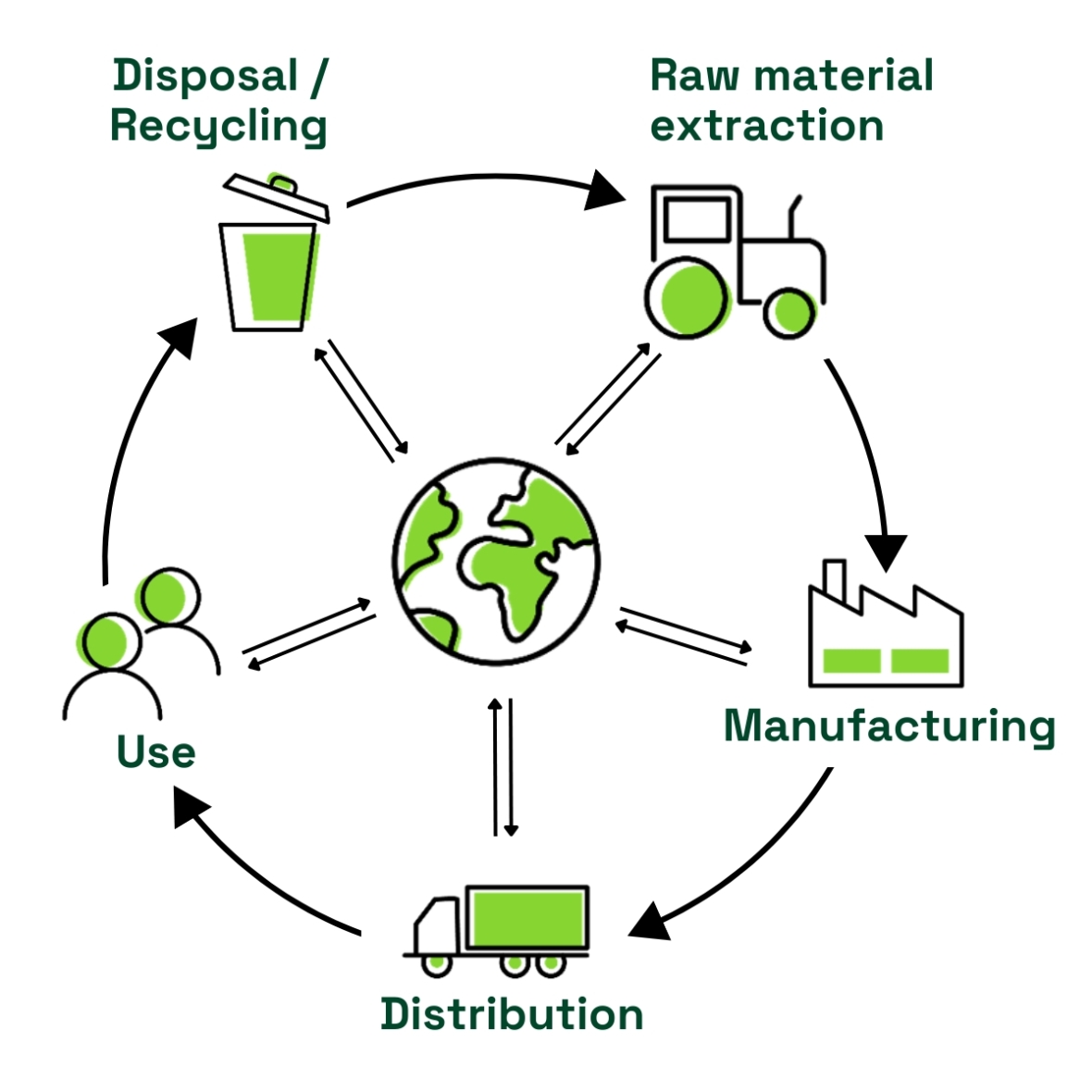

That’s where a life cycle assessment comes in. To use the ISO 14040 definition – the widely accepted international standard for the methodology for life cycle assessments and the standard that the studies for IFCO follow – LCAs involve the "compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product system throughout its life cycle".

The first LCA was conducted in 1969 and involved the comparison of beverage containers for Coca Cola. The focus at the time was on energy consumption and solid waste. Since then, LCAs have broadened the evaluation to include raw materials and emissions. Today, according to a recent report by PriceWaterhouseCoopers, 69% of the businesses they surveyed have already conducted life cycle assessments, but only on less than 25% of their product portfolio.

In a nutshell, an LCA is the systematic analysis of the potential environmental impacts over the whole life cycle of a product, process or service. It covers the sourcing of raw material, manufacturing, distribution, use and disposal/recycling. Each of these stages has impacts associated with material and energy inputs as well as waste outputs.