Our RPCs.

For every fresh product need.

choose Country & Language: / English

Our RPCs.

For every fresh product need.

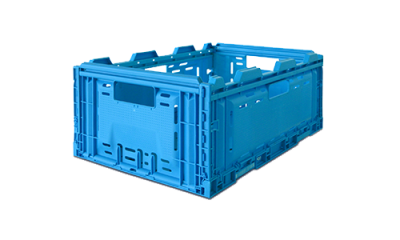

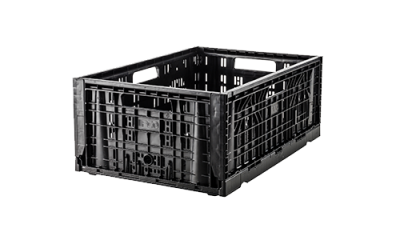

We know the importance of finding the perfect solution for your fresh products – that’s why we have reusable packaging solutions suited for every need. With over 70 models and counting, our display-ready reusable packaging containers (RPCs) come in a wide range of sizes and can safely transport fresh fruit and vegetables, meat, fish and seafood, eggs, baked goods, and deli and convenience products. A true workhorse if you ever saw one.

Reusable again and again, our RPCs also ensure reduced food waste, drive cost savings, extend shelf life of produce, and help your business operate more sustainably. Let’s break up with single-use packaging for good.

Showing series

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for

recommended for