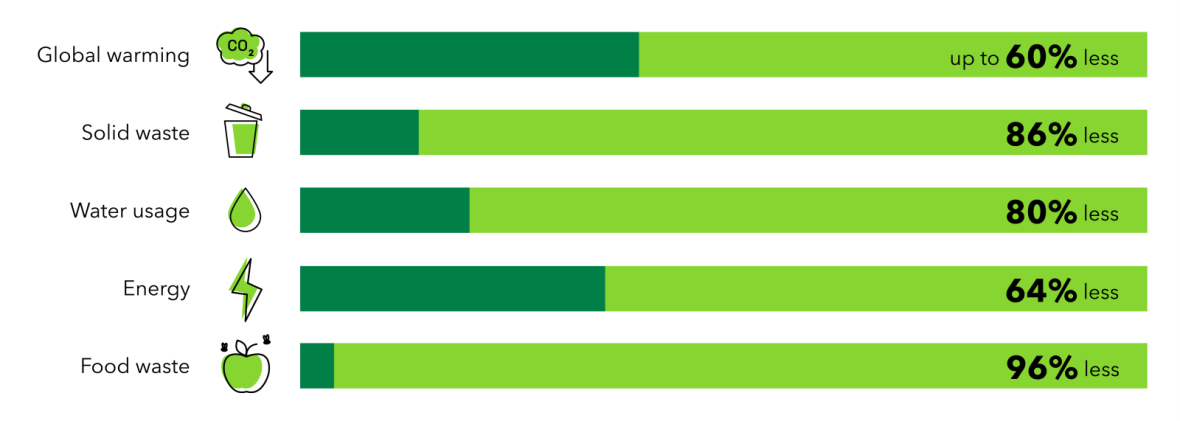

Our products use fewer natural resources than disposable alternatives throughout their lifecycle, from the energy and materials used in their manufacture through cleaning and repair to eventual recycling. And because they perform better in transit – stacking securely and maintaining their structural rigidity – they offer indirect environmental benefits, too. Less food is wasted, so less energy and resources are required to replace damaged stock.

Switching to IFCO Reusable Packaging Containers (RPCs) reduces your supply chains’ impact on the environment: less waste out, fewer natural resources in.

Using IFCO reusable packaging containers (RPCs) instead of single-use packaging means a significant reduction in CO2. That’s because IFCO RPCs are designed to be reused again and again. No need to recycle and remanufacture them after every use like single-use packaging.

IFCO RPCs reduce the creation of solid waste by 86%, thanks to their long lifespan and the fact they are fully recyclable. Each is used between 30 – 120 times before it is removed from service due to wear, damage, or design changes. And at the end of its life, each is granulated and used to create new RPCs.

Water-recycling technology at many of our state-of-the-art wash centers reduces water use by over a third for each wash. By comparison, single-use packaging systems use 80% more water during their lifecycle due to heavy water use during production (regardless of their recycled content), and in the recycling and disposal phases.

RPCs reduce food waste and ensure higher-quality produce in stores. Keeping fresh food fresher for longer, IFCO RPCs translates into less food waste.